Peristaltic Pump

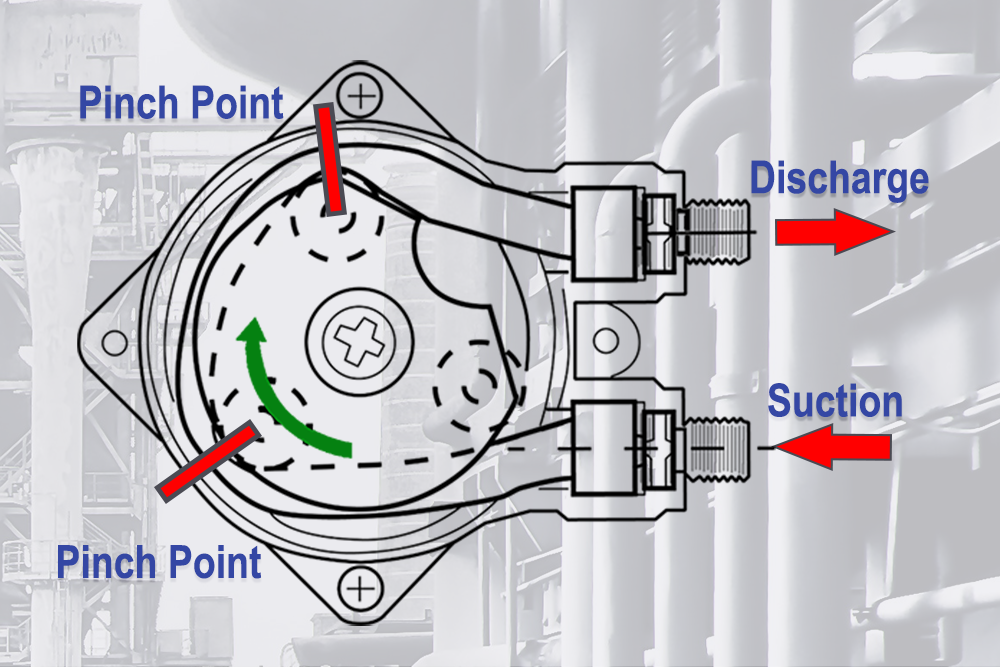

Another staple in the metering pump world is the peristaltic pump. The function of the pump is similar- both dose repeatable and accurate quantities of chemical. Contrarily, the different pump technologies operate quite differently. A peristaltic pump’s head consists of a suction and discharge side. The “wetted” liquid end of the pump is a flexible piece of tubing. Positive displacement is created as the rollers inside the head contact the tubing, creating a pinch point, and rotate around, causing suction on the suction side and positive output pressure on the discharge side. The pinch points in a peristaltic pump are the “seals” in the pump and the rotation of the pinch points that causes a volume change, creating the suction and discharge pressure allowing the pump to operate.

The volume displaced from a single head revolution in a peristaltic pump is fixed based on the size of the tube, but output can be varied by adjusting the speed or rotations per minute of the pump head. Considering the suction and discharge stroke occurs simultaneously you would assume the output of a peristaltic pump to be more consistent; however, the pump operation will create varying fluid acceleration and some pressure swings as each roller goes by the discharge valve.

Functional overview of a peristaltic pump operation.

Pump Selection

These differences in technology cause one pump to excel over another in a given application. From a chemical compatibility standpoint, you typically have better coverage on a diaphragm pump when working with more aggressive chemicals. Dialing in the head material, the elastomers and the check balls typically enable you to select a wet end compatible with the chemical being dispensed into the system. Peristaltic pumps on application considerations including pressure, flow, liquid end life, compatibility, life cycle cost and accuracy tend to be slightly less when compared with diaphragm technology. However, the “self-priming” nature of a peristaltic pump makes it a favorite for many in addition to the heightened performance with small suspended solids. Suspended solids will sit on the valves inside a diaphragm pump and interfere with the check balls seating, which prevents the pump from functioning. Lastly, when it comes to suction lift capacity or the ability of a pump to lift fluid up to the pump head, a peristaltic pump performs better.

You might have been working with metering equipment for 30 years or 30 days; however, no one is perfect. If you have not already, you will eventually make a mistake on choosing the proper equipment for a process or just installing the equipment incorrectly. Some mistakes could lead to not feeding any chemicals for a month, while others might cause a full tote of chemicals to be dumped preemptively into a process. It is difficult to predict every corner case in some applications that could adversely impact your metering equipment. Everyone develops a set of “go-to” equipment and even has a typical installation setup. This can help drive consistency in your various site visits. You have a pump you are comfortable with, know how to rebuild, and maybe already have spare parts lying around in case of an emergency. Sometimes the best pump is simply the one that is there and works; however, you are not always handed accounts that fit your typical equipment selection. Be aware of the dosing equipment needs in each process; factor in for the process variables like output, pressure and compatibility. Scope out your installation conditions, and minimize unnecessary chemical tubing runs. Make sure your equipment can interface with any other existing system when applicable and be aware of any unique environmental conditions which might lead to special equipment considerations.